FSW: Industrial Applications of Friction Stir Welding - Who Achieves the Greatest Benefits?

Translation of Paper Presented at FSW Conference, SLV Berlin-Brandenburg, 27-28 May 2025

Content

1. Industrial Sectors

- Ships, trains, aerospace

- Automotive, especially eMobility

- Air- and water-cooled heat exchangers and battery trays

2. Gantries, CNC-Machines and Robots

- One upgraded CNC-machine is faster than two robots

- FSW head maintains a constant force in aC NC machine

3. Financial Risk and Technical Success

- The efforts for clamping are often underestimated

4. Market Analysis

- FSW machines und FSW tools by region

- SWOT, PESTEL and DROC analyses

5. FSW Standards

- ISO 25239, AWS 17.3 and ASME IX

- DVS guidelines

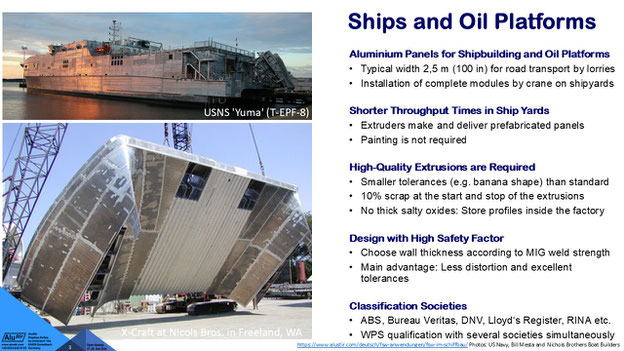

Ships and Oil Platforms

Aluminium Panels for Shipbuilding and Oil Platforms

- Typical width 2,5 m (100 in) for road transport by lorries

- Installation of complete modules by crane on shipyards

Shorter Throughput Times in the Ship Yards

- Extruderes make and deliver prefabricated panels

- Painting is not required

High-Quality Extrusions are Required

- Smaller tolerances (e.g. banana shape) than standard

- 10% scrap at the start and stop of the extrusions

- No thick salty oxides: Store profiles inside the factory

Design with High Safety Factor

- Choose wall thickness according to MIG weld strength

- Main advantage: Less distortion and excellet tolerances

Classification Societies

- ABS, Bureau Veritas, DNV, Lloyd‘s Register, RINA etc.

- WPS qualification with several societies simultaneously

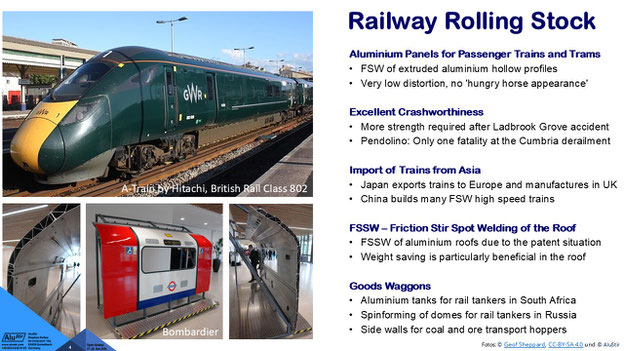

Railway Rolling Stock

Aluminium Panels for Passenger Trains and Trams

- FSW of extruded aluminium hollow profiles

- Very low distortion, no 'hungry horse appearance'

Excellent Crashworthiness

- More strength required after Ladbrook Grove accident

- Pendolino: Only one fatality at the Cumbria derailment

Import of Trains from Asia

- Japan exports trains to Europe and manufactures in UK

- China builds many FSW high speed trains

FSSW – Friction Stir Spot Welding of the Roof

- FSSW of aluminium roofs due to the patent situation

- Weight saving is particularly beneficial in the roof

Goods Waggons

- Aluminium tanks for rail tankers in South Africa

- Spinforming of domes for rail tankers in Russia

- Side walls for coal and ore transport hoppers

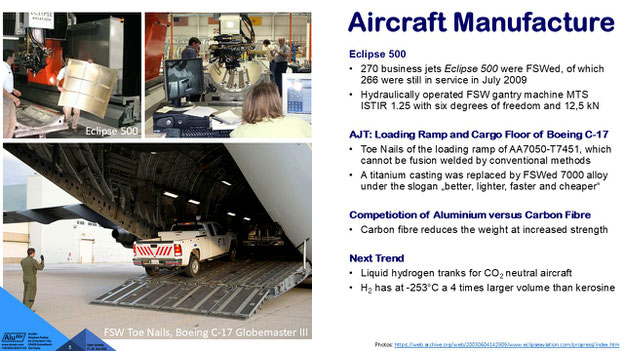

Aircraft Manufacture

Eclipse 500

- 270 business jets Eclipse 500 were FSWed, of which 266 were still in service in July 2009

- Hydraulically operated FSW gantry maschine MTS ISTIR 1.25 with six degrees of freedom and 12,5 kN

AJT: Loading Ramp and Cargo Floor of Boeing C-17

- Toe Nails of the loading ramp of AA7050-T7451, which cannot be fusion welded by conventional methods

- A titanium casting was replaced by FSWed 7000 alloy under the slogan „better, lighter, faster and cheaper“

Competition of Aluminium versus Carbon Fibre

- Carbon fibre reduces the weight at increased strength

Next Trend

- Liquid hydrogen tranks for CO2 neutral aircraft

- H2 has at -253°C a 4 times larger volume than kerosine

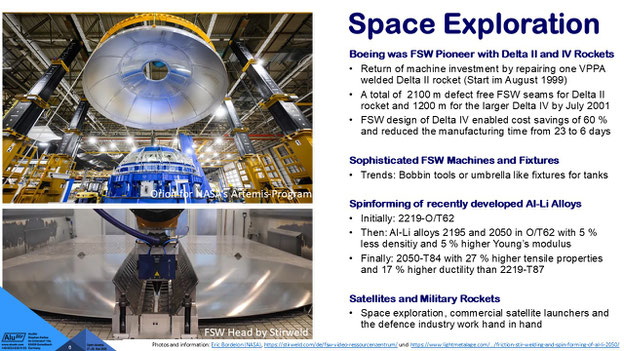

Space Exploration

Boeing was FSW Pioneer with Delta II and IV Rockets

- Return of machine investment by repairing one VPPA welded Delta II rocket (Start im August 1999)

- A total of 2100 m defect free FSW seams for Delta II rocket and 1200 m for the larger Delta IV by July 2001

- FSW design of Delta IV enabled cost savings of 60 % and reduced the manufacturing time from 23 to 6 days

Sophisticated FSW Machines and Fixtures

- Trends: Bobbin tools or umbrella like fixtures for tanks

Spinforming of recently developed Al-Li Alloys

- Initially: 2219-O/T62

- Then: Al-Li alloys 2195 and 2050 in O/T62 with 5 % less densitiy and 5 % higher Young’s modulus

- Finally: 2050-T84 with 27 % higher tensile properties and 17 % higher ductility than 2219-T87

Satellites and Military Rockets

- Space exploration, commercial satellite launchers and the defence industry work hand in hand

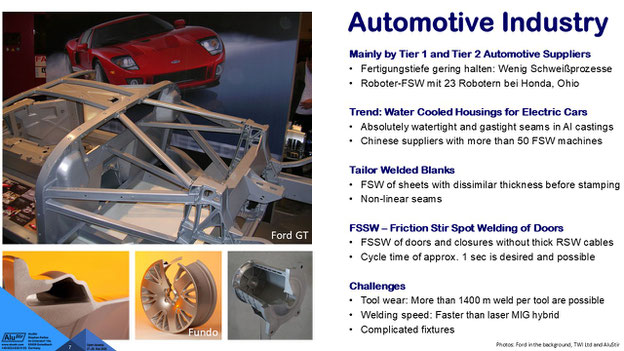

Automotive Industry

Mainly by Tier 1 and Tier 2 Automotive Suppliers

- Fertigungstiefe gering halten: Wenig Schweißprozesse

- Roboter-FSW mit 23 Robotern bei Honda, Ohio

Trend: Water Cooled Housings for Electric Cars

- Absolutely watertight and gastight seams in Al castings

- Chinese suppliers with more than 50 FSW machines

Tailor Welded Blanks

- FSW of sheets with dissimilar thickness before stamping

- Non-linear seams

FSSW – Friction Stir Spot Welding of Doors

- FSSW of doors and closures without thick RSW cables

- Cycle time of approx. 1 sec is desired and possible

Challenges

- Tool wear: More than 1400 m weld per tool are possible

- Welding speed: Faster than laser MIG hybrid

- Complicated fixtures

Heat Exchangers

CNC Milling before and after FSW

- Tailor made aluminium cooling plates or heat exchangers with excellent thermal performance and high versatility at low development cost

- Atherm uses FSW both for small batch production during prototyping (A and B samples), and for large volumes in the serial production

Rotation Speeds during CNC Milling and FSW

- FSW needs comparatively low rotation speeds at high downward pressure

- The Stirweld FSW head protects your spindle bearings against the high forces and process temperatures

- The Stirweld FSW head keeps the downward force constant and measures force and temperature

- Automatic CNC/FSW tool changer and/or FSW head changer

CFD (Computer Fluid Dynamics)

- The thermal properties can be optimised by modelling the heat flow

- Bionic heat exchangers

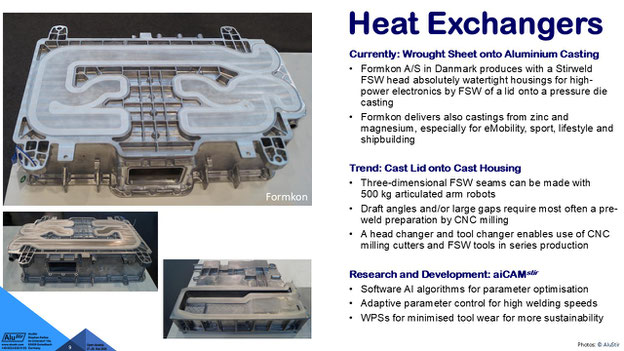

Heat Exchangers

Currently: Wrought Sheet onto Aluminium Casting

- Formkon A/S in Danmark produces with a Stirweld FSW head absolutely watertight housings for high-power electronics by FSW of a lid onto a pressure die casting

- Formkon delivers also castings from zinc and magnesium, especially for eMobility, sport, lifestyle and shipbuilding

Trend: Cast Lid onto Cast Housing

- Three dimensonal FSW seams can be made with500 kg articulated arm robots

- Draft angles and/or large gaps require most often a pre-weld preparation by CNC milling

- A head changer and tool changer enables use of CNC milling cutters and FSW tools in series production

Research and Development: aiCAMstir

- Software AI algorithms for parameter optimisation

- Adaptive parameter control for high welding speeds

- WPSs for minimised tool wear for more sustainability

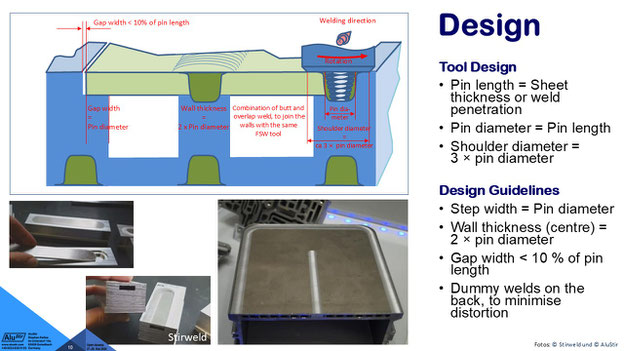

Design

Tool Design

- Pin length = Sheet thickness or weld penetration

- Pin diameter = Pin length

- Shoulder diameter = 3 × pin diameter

Design Guidelines

- Step width = Pin diameter

- Wall thickness (centre) = 2 × pin diameter

- Gap width < 10 % of pin length

- Dummy welds on the back, to minimise distortion

Gantry, CNC Machine or Robotic Cell

Turn-key Solutions

- Planning, specification

- Complete cells incl. fixtures

- Commissioning

- Training, ramp-up

FSW System Integration

- Upgrading of existing CNC milling machines

- New, used und importierted robots

Special Applications

- FSW of steel

- Retractable pin

- Welding speed >3 m/min

Financial Risk

Large Expenses for Research and Development

- Know-how loss by personel changes

- Route cause analysis of non-optimised FSW tools

Underestimation of Clamping Efforts

- Aircraft manufacturers, GIL pipelines and eMobility

Competition with Material Suppliers who Add Value

- Aluminium extruders demand surcharges for tolerances

- Steel and plastics are cheaper than aluminium

Market develops more slowly than predicted

- High sales cost of the FSW machine manufacturers

Peaks of Orders and Sales

- Expensive special machines especially for aerospace

- Excess and shortage quantities in automotive market

Unexpected Political Decisions

- Changing laws and tolls, wars, governmental funding

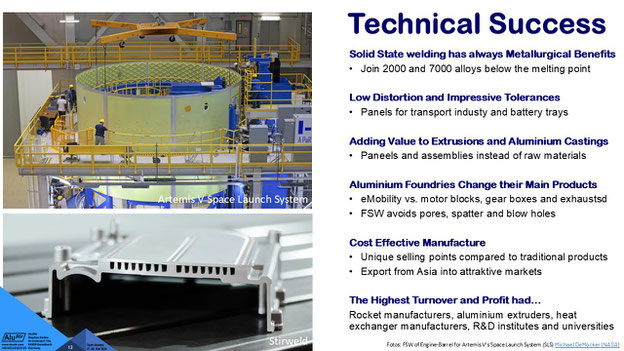

Technical Success

Solid State welding has always Metallurgical Benefits

- Join 2000 and 7000 alloys below the melting point

- Low Distortion and Impressive Tolerances

- Panels for transport industy and battery trays

Adding Value to Extrusions and Aluminium Castings

- Paneels and assemblies instead of raw materials

Aluminium Foundries Change their Main Products

- eMobility vs. motor blocks, gear boxes and exhaustsd

- FSW avoids pores, spatter and blow holes

Cost Effective Manufacture

- Unique selling points compared to traditional products

- Export from Asia into attraktive markets

The Highest Turnover and Profit had…

- Rocket manufacturers, aluminium extruders, heat exchanger manufacturers, R&D institutes and universities

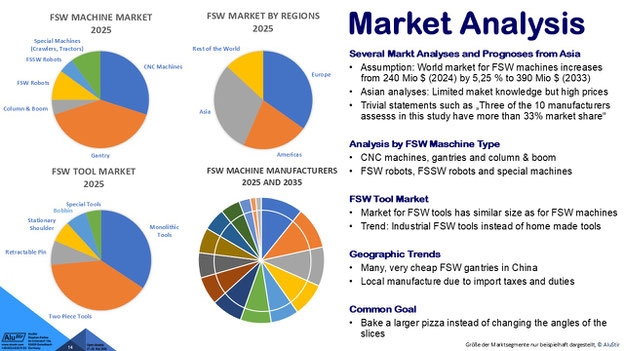

Market Analysis

Several Markt Analyses and Prognoses from Asia

- Assumption: World market for FSW machines increasesfrom 240 Mio $ (2024) by 5,25 % to 390 Mio $ (2033)

- Asian analyses: Limited maket knowledge but high prices

- Trivial statements such as „Three of the 10 manufacturers assesss in this study have more than 33% market share.“

Analysis by FSW Maschine Type

- CNC machines, gantries and column & boom

- FSW robots, FSSW robots and special machines

FSW Tool Market

- Market for FSW tools has similar size as for FSW machines

- Trend: Industrial FSW tools instead of home made tools

Geographic Trends

- Many, very cheap FSW gantries in China

- Local manufacture due to import taxes and duties

Common Goal

- Bake a larger pizza instead of changing the angles of the slices

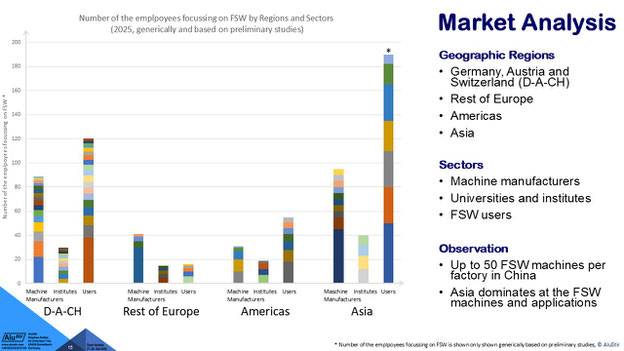

Market Analysis

Geographic Regions

- Germany, Austria and Switzerland (D-A-CH)

- Rest of Europe

- Americas

- Asia

Sectors

- Mashine manufacturers

- Universities and institutes

- FSW users

Observations

- Up to 50 FSW machines per factory in China

- Asien dominates at the FSW machines and applications

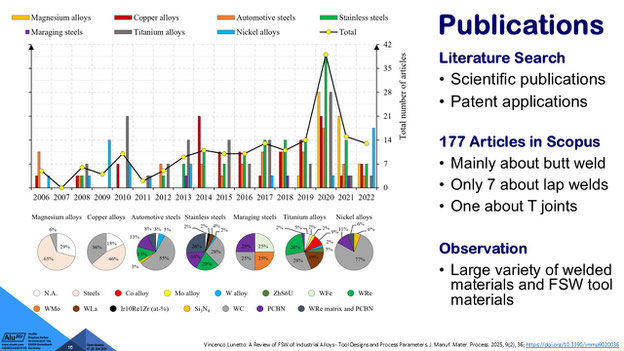

Publications

Literature Search

- Scientific publications

- Patent applications

177 Articles in Scopus

- Mainly about butt weld

- Only 7 about lap welds

- One about T joints

Observation

- Large variety of welded materials and FSW tool materials

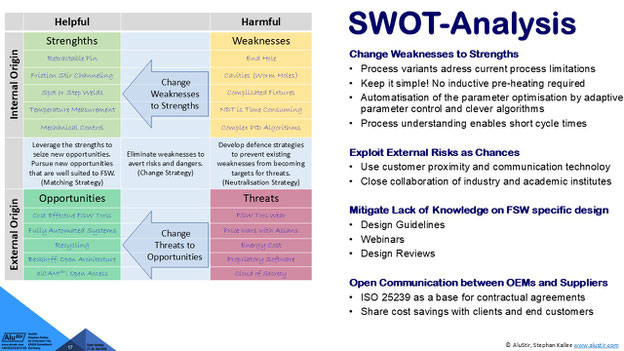

SWOT Analysis

Change Weaknesses to Strengths

- Process variants adress current process limitations

- Keep it simple! No inductive pre-heating required

- Automatisation of the parameter optimisation by adaptive parameter control and clever algorithms

- Process understanding enables short cycle times

Exploit External Risks as Chances

- Use customer proximity and communication technoloy

- Close collaboration of industry and academic institutes

Mitigate Lack of Knowledge on FSW specific design

- Design Guidelines

- Webinars

- Design Reviews

Open Communication between OEMs and Suppliers

- ISO 25239 as a base for contractual agreements

- Share cost savings with clients and end customers

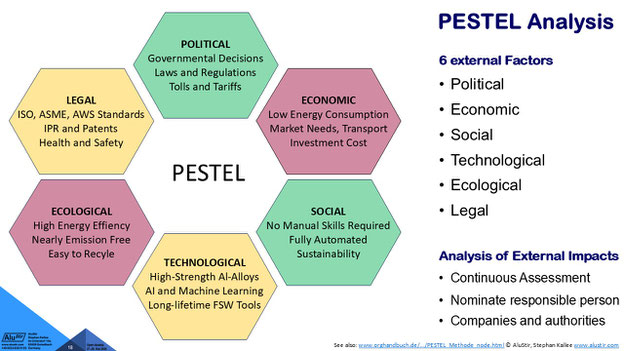

PESTEL Analysis

Six external Factors

- Political

- Economic

- Social

- Technological

- Ecological

- Legal

Analysis of External Impacts

- Continuous Assessment

- Nominate responsible person

- Companies and authorities

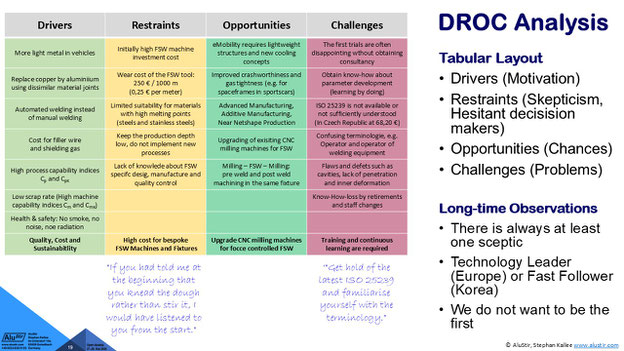

DROC Analysis

Tabular Layout

- Drivers (Motivation)

- Restraints (Skepticism, Hesitant decisision makers)

- Opportunities (Chances)

- Challenges (Problems)

Long-time Observations

- There is always at least one sceptic

- Technology Leader (Europe) or Fast Follower (Korea)

- We do not want to be the first

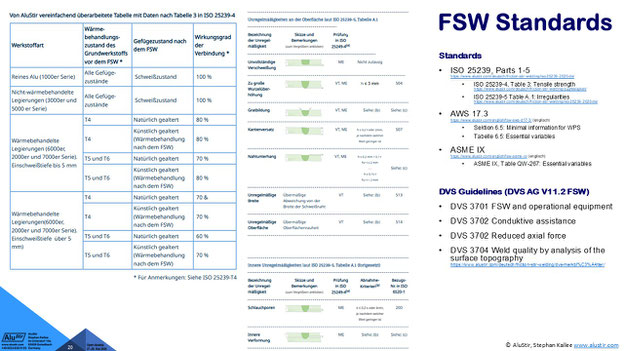

FSW Standards

Standards

- ISO 25239, Parts 1-5

- ISO 25239-4, Table 3: Tensile strength

- ISO 25239-5 Table A.1: Irregularities

- AWS 17.3 (englisch)

- Sektion 6.5: Minimal information for WPS

- Tabelle 6.5: Essential variables

- ASME IX (englisch)

- ASME IX, Table QW-267: Essential variables

DVS Guidelines (DVS AG V11.2 FSW)

- DVS 3701 FSW and operational equipment

- DVS 3702 Conduktive assistance

- DVS 3702 Reduced axial force

- DVS 3704 Weld quality by analysis of the surface topography

Who achieves the largest Benefits?

Space Exploration

- FSW has revolutionised rocket manufacture worldwide

- High-strength aluminium alloys are weldable by FSW

Adding Value

- Panels instead of extrusions

- Parallel welds with low distortion and superb tolerances

Cooling Plates (Thermal Management)

- More than 1000 m per day for heat exchangers

- FSW of aluminium die castings without pores or spatter

Mixed Material Joints

- Lap welding of aluminium-copper or aluminium-steel

- Combination of wrought sheet, extrusions and castings

Research & Development at Universities and Institutes

- Many publications and patents

- Re-invention and research of previously well-known facts

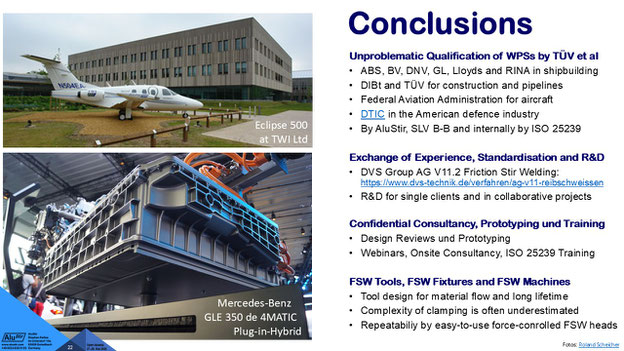

Conclusions

Unproblematic Qualification of WPSs by TÜV et al

- ABS, BV, DNV, GL, Lloyds and RINA in shipbuilding

- DIBt and TÜV for construction and pipelines

- Federal Aviation Administration for aircraft

- DTIC in the American defence industry

- By AluStir, SLV B-B and internally by ISO 25239

Exchange of Experience, Standardisation and R&D

- DVS Group AG V11.2 Friction Stir Welding:https://www.dvs-technik.de/verfahren/ag-v11-reibschweissen

- R&D for single clients and in collaborative projects

Confidential Consultancy, Prototyping und Training

- Design Reviews und Prototyping

- Webinars, Onsite Consultancy, ISO 25239 Training

FSW Tools, FSW Fixtures and FSW Machines

- Tool design for material flow and long lifetime

- Complexity of clamping is often underestimated

- Repeatabiliy by easy-to-use force-conrolled FSW heads