FSW: Variants

Explanations, Acronyms, Abbreviations and Trademarks of Friction Stir Welding and its Variants

The following acronyms are used in various publications on friction stir welding and its variants. Some of them have a double-meaning:

FSC — Friction Stir Channelling

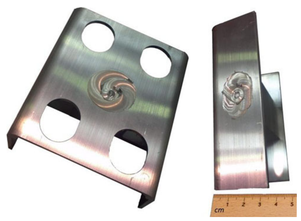

FSC — Friction Stir Channeling: (a) Specifications on probe thread profile for FSC of a AA5083-H111 plate (dimensions in mm); (b) The assembled FSC-tool with shoulder and probe; (c) Clamping jig used for the making FSC samples in the laboratory[1]

© Heikki Karvinen , Afshin Hasani Aleni, Pauli Salminen , Tatiana Minav and Pedro Vilaça, CC BY 4.0

Friction Stir Channelling (FSC) is a solution for producing internal closed channels along a desired path with a constant or continuously modified shape along the path in a single manufacturing step. The channels are formed by continuous extraction of part of the plasticised workpiece material into the external flash.[1]

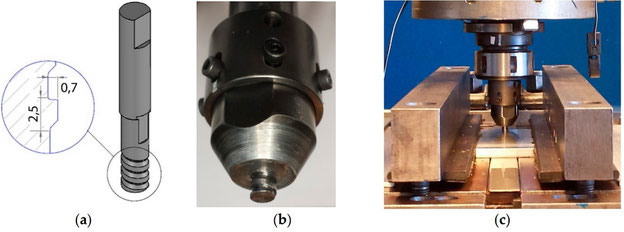

FSC — Friction Stir Channeling: Macrograph of the cross-section of the channel with the metallurgical zones of interest: 1—top corner of retreating side, 2—middle part of the ceiling, 3—top corner of the advancing side, 4—bottom corner of the advancing side, 5—middle part of the bottom and 6- bottom corner of the retreating side[1]

© Heikki Karvinen , Afshin Hasani Aleni, Pauli Salminen , Tatiana Minav and Pedro Vilaça, CC BY 4.0

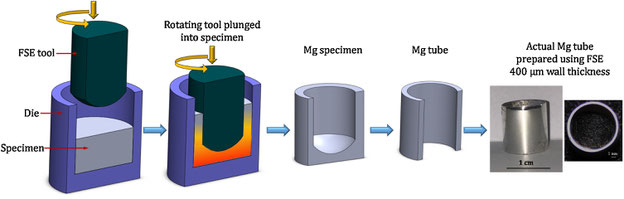

FSE — Friction Stir Extrusion

FSE — Friction Stir Extrusion of ultra-thin wall biodegradable magnesium alloy tubes[18]

© Vasanth C. Shunmugasamya, Eisha Khalida, Bilal Mansoor, CC BY 4.0

Friction stir extrusion (FSE) was used in 2020/21 to produce thin-walled biodegradable tubes, which corrode from the outside after being implanted into the body of a human or animal. Biodegradable tubular structures such as stents are routinely deployed for various short-term medical interventions. The biodegradability can eliminate the need for secondary procedures associated with conventional stents.[18]

The coronary stents manufacture require defect-free, high-quality tubes with thin walls (0.1 mm – 1 mm) as a precursor. Fully consolidated, structurally sound ultra-thin walled (∼ 400 μm) AZ31 Mg alloy tubes by friction stir back extrusion (FSE) — a process used typically to manufacture thick metallic tubes and rods.[18]

The tube cross-sectional microstructure was layered and consisted of a severely deformed stir zone with refined grains near the inner edge, a back-extruded zone with small grains near the outer edge, and a thermomechanically affected zone (TMAZ) with coarse grains develop within the central region. The inner tube surface microstructure had an average grain size of 4.1 ± 1.9 μm and a strong basal texture. In comparison, the outer tube surface microstructure was coarse, with an average grain size of 13.3 ± 6.4 μm with no preferred orientation.[18]

Upon exposure to Hank’s balanced salt solution at 37 °C, microgalvanic coupling resulting from the gradient through-the-thickness grain size and texture differences between the tube inner and outer surfaces, and residual strain arising from the FSE process, promoted a localized attack that preferentially initiated on the outer tube surface and progressed inwards. The study established that FSE is a viable single-step process to manufacture ultra-thin Mg alloy tubes suitable for degradable precision tubular applications.[18]

PFSW* — Plasma Assisted Friction Stir Welding

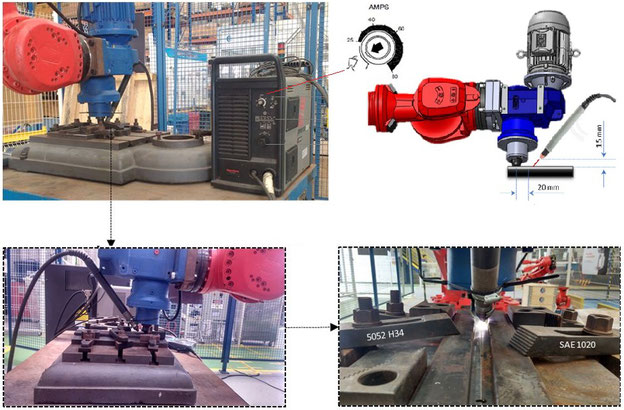

PFSW — Plasma Assisted Friction Stir Welding with a 500kg payload COMAU robot NJ5000, a bespoke FSW spindle and a Hyperterm Powermax 1250® 80 A plasma cutter

© Bruno Silva Cota (UNIFEI) and Alexandre Queiroz Bracarense (UFMG), CC BY-NC 4.0

Experimental trials were conduced in Brasil on using Plasma Assisted Friction Stir Welding (PFSW*) for dissimilar material combinations of joining 3 mm thick SAE 1020 carbon steel sheets to 3 mm thick 5052 H34 aluminum sheets using an offset of 0 or -2.5 mm. The plasma torch was used to preheat the steel to 250 °C, 350 °C or 450 °C. Further parameter development trials are recommended to improve the weld quality and reduce tool wear.[19]

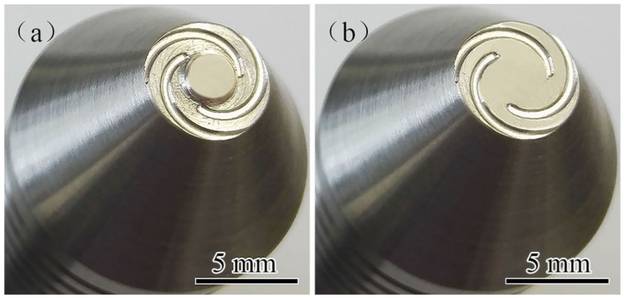

PFSW* — Pinless Friction Stir Welding

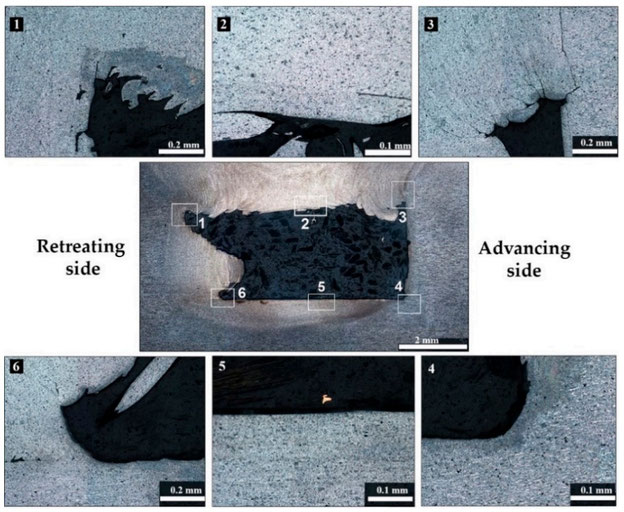

PFSW — Pinless Friction Stir Welding[13]

© Yu Ni, Yue Mao, Dingqiang Qin, Xuan Xiao and Li Fu (Xi’an, China), CC BY 4.0

Pinless Friction Stir Welding (PFSW*) was used for instance by Zhenlei Liu et al in 2016 for making thin wall structures from Alclad 2A12-T4 alloy.[14] Yu Ni et al later conducted successfully a study on μFSW of 0.5 mm thick AA7075-T6 sheets with a thickness of 0.5 mm in Xi’an, China in the butt joint configuration. The influence of the welding process on the thermal cycles and deformations of μFSW was systematically studied through experiments. They concluded that "in comparison to the pin tool, the joint fabricated by the pinless tool experienced a lower peak temperature, a shorter elevated-temperature exposure time, and a larger temperature gradient within the shoulder range under the same shoulder penetration depth."[13]

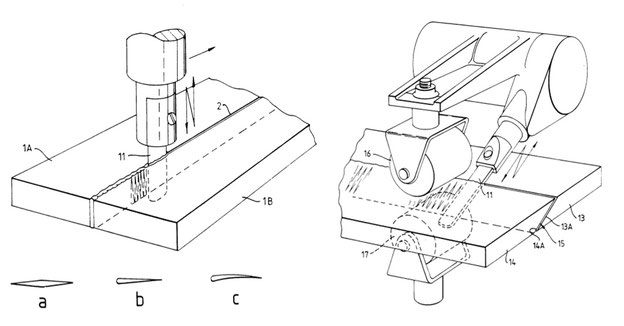

Reciprocating FSW

Reciprocating friction stir welding is particularly useful for welding plastics, as shown in the first patent of Wayne Thomas at TWI[8]

Courtesy of TWI Ltd.

RFSW — Robotic Friction Stir Welding

Closed-loop temperature control can be used in Robotic Friction Stir Welding (RFSW) for modifying the spindle rotation speed to maintain a constant welding temperature. For industrial applications this will reduce the programming time and increase the robustness of the process. By measuring the ohmic resistance between the tool and the work piece it is possible to assess the processing temperature without the need for thermocouples inside the tool. The method can be used used to control both plunging and welding.[25][26]

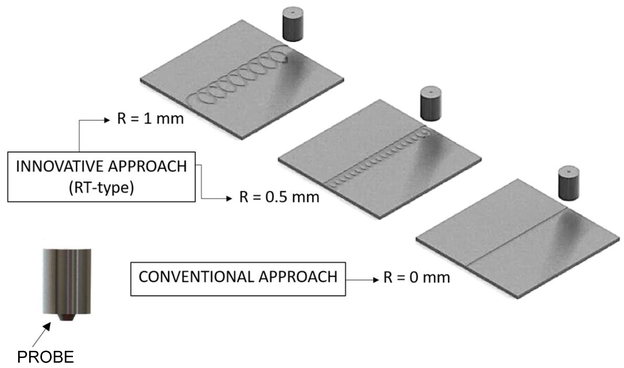

RT-FSW — Combined Rotation and Translation of the Tool Axis (commonly known as Com-stir™)

RT-FSW: Combined rotation and translation of the tool axis (Com-stir™)

© Marcello Cabibbo, Archimede Forcellese, Eleonora Santecchia, Chiara Paoletti, Stefano Spigarelli and Michela Simoncini, CC BY 4.0

Wayne Thomas, the inventor of friction stir welding, developed and published also

Com-stir™, a compound motion for FSW and machining, using a rotary motion in combination with an orbital motion.[6]

The benefits of this motion have been confirmed by several researchers, and Cabibbo et al. described this as an "approach in which welding pin was forced to slightly deviate away from the joining centreline (defined by authors as RT)", i.e. an "innovative approach to the conventional FSW process, defined by authors as RT-type configuration, in which the welding motion of the pin tool was obtained by combining two different movements occurring simultaneously:[12][13]

(i) the rotation of the pin axis around an axis, perpendicular to the sheet blanks and belonging to the welding line, with a radius equal to R, and

(ii) the translation of the pin axis along a direction parallel to the welding line."[12]

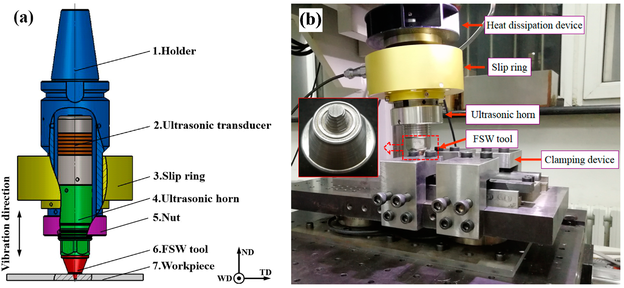

UAFSW — Ultrasonically Assisted FSW

UAFSW — Ultrasonically assisted friction stir welding concept and device[10, retouched]

© Zhiqiang Zhang, Changshu He, Ying Li, Jingxun Wei, Menggang Zhai, Su Zhao and Xiang Zhao, CC BY 4.0

Ultrasonic vibration promotes the flow of metal at the interface, enlarged the size of the stirred zone (SZ), and reduced the angle between the hook defect and the interface. It was observed that, under otherwise identical conditions, UAFSLW joints can withstand a greater fracture shear strength than FSLW joints, as ultrasonic vibration helps to mix the material at the interface, thus, enlarging the SZ and diminishing the cold lap defects.[10]

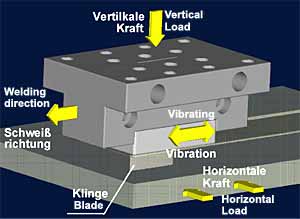

Viblade™ Welding — In-line Reciprocating FSW

Viblade™ Welding — In-line Reciprocating Friction Stir Welding: Schematic, photo and macrosections of some of the first welds made in 9 mm thick polypropylene sheet

Courtesy of TWI Ltd.

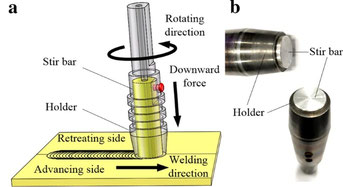

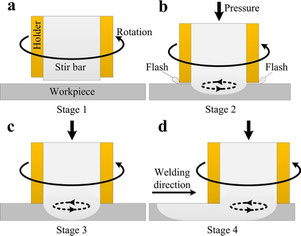

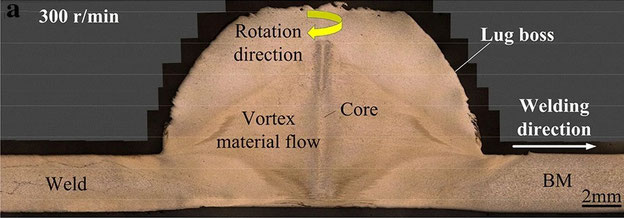

VFSW — Vortex Friction Stir Welding

VFSW — Vortex Friction Stir Welding: Principle, tool and shematic side view

© Xiaochao Liu, Yunqian Zhen, Zhikang Shen, Haiyan Chen, Wenya Li, Wei Guo and Zhufeng Yue, CC BY 4.0

For Vortex Friction Stir Welding (VSFW) the tool is partially made from the same material as the workpiece material. The process depends on a vortex material flow to make the weld. The weld macro- and micro-structures look similar to those of conventional FSW. However, in VSFW a lug boss is left at the end of the weld instead of an exit-hole as in conventional FSW. The mechanical properties are similar or even identical to those in conventional FSW.[24]

VFSW — Vortex Friction Stir Welding: Metallographic section of lug boss at end of weld

© Xiaochao Liu, Yunqian Zhen, Zhikang Shen, Haiyan Chen, Wenya Li, Wei Guo and Zhufeng Yue, CC BY 4.0

Acronyms Related to Friction Stir Welding and its Variants and Derivatives (non-exhaustive)

- AFSD — Additive Friction Stir Deposition

-

AFSW* — Autogenous Friction Stir Welding

-

AFSW* — Assisted Friction Stir Welding (hybrid)

- BFSW — Bobbin Friction Stir Welding

- CFSW — Cooled Friction Stir Welding

- DFSW — Dissimilar Friction Stir Welding

- DP-FSSW — Double-side Probeless Friction Stir Spot Welding[36]

- DS-FSW — Double Side Friction Stir Welding

- EAFSW — Electrically Assisted Friction Stir Welding**

- EFSW — Electrically Assisted Friction Stir Welding**

- FBJ — Friction Bit Joining[2]

- FFSW — Filling Friction Stir Welding

- FMB — Friction Melt Bonding[2]

- FSADW — Friction Stir Assisted Diffusion Welding[2]

- FSAM — Friction Stir Additive Manufacturing[30]

- FSB — Friction Stir Brazing[2]

- FSBR — Friction Stir Blind Rivetting[38]

- FSC* — Friction Stir Chanelling[1][21][22]

- FSC* — Friction Stir Clinching[28]

- FSD — Friction Stir Dovetailing[2]

- FSE — Friction Stir Extrusion[2]

- FSLW — Friction Stir Lap Welding[20]

- FSP — Friction Stir Processing

- FSpW — Friction Spot Welding[39]

- FSS welding — friction stir scribe welding

- FSSAW — Friction Stir Spot Adhesive Welding[33]

- FSSFW — Friction Stir Spot Fusion Welding[2]

- FSSW — Friction Stir Spot Welding

- FSW — Friction Stir Welding

- GFSW — Gas Torch (assisted) Friction Stir Welding

- GTAFSW — Gas Tungsten Arc (assisted) Friction Stir Welding

- HFSC — Hybrid Friction Stir Channeling[24]

- HFSW — Hybrid Friction Stir Welding[2]

- HSFSW — High rotation speed friction stir welding[42]

- IFSW — Impulse Friction Stir Welding

- i-FSW — Induction heating tool assisted Friction Stir Welding

- IPFSW — Induction Preheated Friction Stir Welding[32]

- LFSW — Laser assisted Friction Stir Welding

- LFSW — Linear Friction Stir Welding (used as a synonym for FSW)[14]

- LAFSW — Laser Assisted Friction Stir Welding

- M-FSW — Multi-pass friction stir processing[41]

- MPT — Multi-Pin Tool

- MFSW — Modified Friction Stir Welding

- µFSW — Micro Friction Stir Welding

- NFSW — Normal Friction Stir Welding

- OFSW — Orbital Friction Stir Welding

- RFSJ — Refill Friction Spot Joining[36]

- PFSW* — Penetrating Friction Stir Welding

- PFSW* — Pinless Friction Stir Welding

- PFSW* — Plasma Friction Stir Welding[19]

- PFSW* — Portable Friction Stir Welding[9]

- QFSW — Heat input of Friction Stir Welding

- RAFSW — Right Angle Friction Stir Welding[16]

- RFSW — Robotic Friction Stir Welding[25][26]

- RFSSW — Refill Friction Stir Spot Welding[40]

- RT-FSW — Rotation and Translation of the Tool Axis (Com-stir™)

- SBT tunneling — Submerged bobbin tool (SBT) tunneling[43]

- SFSW — Submerged Friction Stir Welding

- SSCA FSW — Stationary Shoulder Corner Angle Friction Stir Welding

- SSFSW — Stationary Shoulder Friction Stir Welding

- SSFSC — Stationary Shoulder Friction Stir Chanelling[31]

- SRFSLW — Self-Riveting Friction Stir Lap Welding[17]

- SRFSW — Self Reacting Friction Stir Welding

- TFSWBs — Tailor Friction Stir Welded Blanks

- T-FSW — FSW of T-joints[29]

- TSW — Thermal Stir Welding

- UAFSW — Ultrasonically Assisted Friction Stir Welding

- UAFSLW — Ultasonically Assisted Friction Stir Lap Welding[20]

- UFSW — Underwater Friction Stir Welding

- USE-FSW — UltraSound Enhanced Friction Stir Welding[44]

- VFSW — Vortex Friction Stir Welding[24]

Trademarks Related to Friction Stir Welding and its Variants and Derivatives (non-exhaustive)

- ESAB: Legio™— standardized and modular FSW machines

- ESAB: Rosio™ — FSW robots

- ESAB: SuperStir™ — Custom-built FSW machinery

- Mazak: MegaStir™ — Machines, tools and consulting services for FSW

- PaR Systems: AdAPT™ — Adaptable Adjustable Pin Tool

- PTG Holyrod: PowerStir™ — Solution provider for high-strength FSW machines

- Stirlink: RoboStir™ — Robotic FSW

- Stirtec: MaXstir™ — FSW tools that are characterized by high functionality, process reliability, high wear resistance and associated high tool life

- TWI: Com-stir™ — Compound motion for FSW and machining, using a rotary motion in combination with an orbital motion[6]

- TWI: CoreFlow™ — A Sub-Surface Machining Process

- TWI: MX-Triflute™ — Multihelix FSW tool

- TWI: Pro-stir™ — Near-Net Shaped Manufacture by FSW[5]

- TWI: Re-stir™ — FSW with reversal of the direction of the tool rotation, which is imposed after one or more revolutions[7]

- TWI: Skew-stir™ — FSW method in that the axis of the tool is given a slight inclination (skew) to that of the machine spindle (also: A-Skew™ probe)[7]

- TWI: Stir-lock™ — An ‘in-process’ forge/forming seam joining technique[5]

- TWI: Twin-stir™ — Using two FSW tools either parallely side-by-side transverse to the welding direction or tandem in-line with the welding direction or staggered to ensure the edges of the weld regions partially overlap[7]

- TWI: Viblade™ — Friction Stir Welding (in-line reciprocating FSW)[3[4]

- TWI: Whorl™ — Frustum-shaped probe with a logarithmic spiral like a nautilus

- Wichita State University: Wiper™ — Tool shoulder with ridge around the scrolls[25]

* Ambiguity (Double Meaning)

* Acronyms marked with an asterisk are synonymously used for several variants, and their use is therefore disencouraged without an explanation. The P in the acronym PFSW can, for instanstance, be interpreted as penetrating, pinless, plasma or portable.

** Some variants can be abreviated by several acronyms, e.g. EFSW and EAFSW for Electrically Assisted Friction Stir Welding.

References

- Heikki Karvinen , Afshin Hasani Aleni, Pauli Salminen , Tatiana Minav and Pedro Vilaça: Thermal Efficiency and Material Properties of Friction Stir Channelling Applied to Aluminium

Alloy AA5083. Energies 2019, 12(8), 1549; https://doi.org/10.3390/en12081549. 26 April 2019.

- Kush P. Mehta: A

review on friction-based joining of dissimilar aluminum–steel joints. Cambridge University Press: 17 October 2018.

-

A Scialpi, M Troughton, S Andrews and L A C De Filippis: In-Line Reciprocating Friction Stir Welding of Plastics. Joining Plastics/Fügen von Kunststoffen. Magazine, Issue 1, May 2007.

-

A Scialpi, M Troughton, S Andrews and L A C De Filippis (deutsche Übersetzung von Stephan Kallee): Rührreibschweissen von Plastik mit einer vibrierenden Vorwärts- und Rückwärtsbewegung des Werkzeugs. Joining Plastics/Fügen von Kunststoffen. Magazine, Issue 1, May 2007.

- Wayne M Thomas, D G Staines, I M Norris, E R Watts: Friction Stir Welding – Process Developments. Conference: Twelfth International

Conference on the Joining of Materials (JOM-12). Helsingor, Denmark. March 2005.

- W M Thomas, I M Norris, D G Staines, PJ Clarke and N L Horrex : Friction stir welding –

variants and process techniques Friction stir welding – variants and process techniques. The First International Conference ‘Joining of Aluminium Structures’ Moscow. 3-5 December

2007.

- W M Thomas, M J Russell, A Duncan and A Robelou : Friction stir

welding, an introduction to

innovative variant techniques for the aluminium industry. 2nd International Aluminium Congress and Exposition, Queretaro, Mexico, 16 - 19 June 2010.

- Wayne M. Thomas, E. Dave Nicholas, James C. Needham, Michael G. Murch, Peter Temple-Smith und Christopher J. Dawes (The Welding Institute): Improvements relating to friction

welding. Europäische Patentschrift EP 0 615 480 B1, Anmeldedatum 6. Dezember 1991.

-

CTC-led Repair Technologies

Deployed on Navy Ship - Aluminum Sensitization Solutions Reduce Costs and Improve Readiness. Johnstown, Pennyslvania, 3. Februar 2021.

- Zhiqiang Zhang, Changshu He, Ying Li, Jingxun Wei, Menggang Zhai, Su Zhao and Xiang Zhao: Fatigue Behaviour of 7N01-T4 Aluminium Alloy Welded by Ultrasonic-Assisted Friction Stir Welding. Materials 2020, 13(20),

4582;https://doi.org/10.3390/ma13204582

- Marcello Cabibbo, Archimede Forcellese, Eleonora Santecchia, Chiara Paoletti, Stefano Spigarelli and Michela Simoncini: New Approaches to Friction Stir

Welding of Aluminum Light-Alloys. Metals 2020, 10(2), 233, https://doi.org/10.3390/met10020233

- Cabibbo, M.; Forcellese, A.; Simoncini, M.; Pieralisi, M.; Ciccarelli, D.: Effect of welding motion and pre-/post-annealing of friction stir welded AA5754 joints. Mater. Des. 2016,

93, 146–159, https://doi.org/10.1016/j.matdes.2015.12.099.

- Yu Ni, Yue Mao, Dingqiang Qin, Xuan Xiao and Li Fu (Xi’an, China):

Thermal Cycles and Deformation Characters During High-Speed Micro Friction Stir Welding Process of AA7075-T6 Sheets. Metals 2019, 9(11), 1236; https://doi.org/10.3390/met9111236.

- Francesco Lambiase, Hamed Aghajani Derazkola and Abdolreza Simchi: Friction Stir Welding and Friction Spot Stir Welding Processes of Polymers—State of the Art. Materials (Basel). 2020 May; 13(10): 2291.

15 May 2020. https://dx.doi.org/10.3390%2Fma13102291.

- Zhenlei Liu, Hutao Cui, Shude Ji, Minqiang Xu, Xiangchen Meng: Improving Joint Features and Mechanical Properties of Pinless Fiction Stir Welding of Alcald 2A12-T4 Aluminum Alloy,

Journal of Materials Science & Technology, Volume 32, Issue 12, 2016. Pages 1372-1377, ISSN 1005-0302, https://doi.org/10.1016/j.jmst.2016.07.003.

- Mahboubeh Momeni and Michel Guillot (Laval University, Québec): Effect of Tool Design and Process Parameters on Lap Joints Made by Right Angle Friction Stir Welding (RAFSW). J. Manuf. Mater. Process.

2019, 3(3), 66; https://doi.org/10.3390/jmmp3030066.

- Yongxian Huang, Tifang Huang, Long Wan, Xiangchen Meng and Li Zhou (Harbin, China): Material

flow and mechanical properties of aluminum-to-steel self-riveting friction stir lap joints. Journal of Materials Processing Technology, No 263, August 2018, https://doi.org/10.1016/j.jmatprotec.2018.08.011

- Vasanth C. Shunmugasamya, Eisha Khalida, Bilal Mansoor (Texas A&M University at Qatar and in Texas): Friction stir extrusion of ultra-thin wall biodegradable magnesium alloy tubes — Microstructure and

corrosion response. Materials Today Communications, Volume 26, 2021, 102129, ISSN 2352-4928, https://doi.org/10.1016/j.mtcomm.2021.102129.

- Bruno Silva Cota (UNIFEI) and Alexandre Queiroz Bracarense (UFMG): Soldagem Dissimilar da Liga de Alumínio 5052 H34 e do Aço SAE 1020 pelo

Processo Hybrid Friction Stir Welding Assistido por Plasma: Análise da Resistência Mecânica, do Desgaste da Ferramenta e dos Esforços de Soldagem (Hybrid Friction Stir Welding Process with

Plasma-assisted of 5052 H34 Aluminum Alloy and SAE 1020 Steel: Analysis of Mechanical Strength, Tool Wear and Welding Stresses). Soldagem & Inspeção, Vol. 25, São Paulo, 27 April

2020, https://doi.org/10.1590/0104-9224/si25.09, CC BY-NC 4.0.

- Changshu He, Zhiqiang Zhang, Ying Li, Jingxun Wei, Menggang Zhai, Su Zhao and Xiang Zhao: Interface Characteristics and Mechanical Properties of Ultrasonic-Assisted Friction Stir Lap Welded 7075-T6 Aluminium Alloy.

Materials 2020, 13(23), 5335; https://doi.org/10.3390/ma13235335. 25 November

2020. CC BY 4.0.

- Catarina Vidal, Virgínia Infante and Pedro Vilaça: Monitoring of the mechanical load and thermal history during friction stir channelling under constant position and

constant force control modes. Journal of Manufacturing Processes, Volume 49, 2020. Pages 323-334, SSN 1526-6125, https://doi.org/10.1016/j.jmapro.2019.11.016.

- Catarina Vidal, Virgínia Infante and Pedro Vilaça: Metallographic and morphological characterization of sub-surface friction stirred channels produced on AA5083-H111. The

International Journal of Advanced Manufacturing Technology volume 105, pages 2215–2235 (2019).

- Xiaochao Liu, Yunqian Zhen, Zhikang Shen, Haiyan Chen, Wenya Li, Wei Guo and Zhufeng Yue: A Modified Friction Stir Welding Process Based on Vortex Material Flow. Chin. J. Mech. Eng. 33, 90 (2020). https://doi.org/10.1186/s10033-020-00499-3. 1 December 2020.

- Heikki Karvinen, Daniel Nordal, Timo Galkin and Pedro Vilaça: Application of hybrid friction stir channeling technique to improve the cooling efficiency of electronic components.

Weld World 62, 497–509 (2018). https://doi.org/10.1007/s40194-018-0576-8.

- Dwight Burford, Christian Widener and Bryan Tweedy:

Advances in Friction Stir Welding for aerospace applications. Airframer, Issue 14, November 2006. https://arc.aiaa.org/doi/10.2514/6.2006-7730. Also on Yumpu.

- Jeroen De Backer, Gunnar Bolmsjö and Anna-Karin Christiansson: Temperature control of robotic friction stir welding

using the thermoelectric effect. In: The International Journal of Advanced Manufacturing Technology 70(1-4). DOI:

10.1007/s00170-013-5279-0, 14 September 2013, CC BY 2.0.

- Ana Catarina Ferreira Magalhães: Thermoelectric Measurements for

Temperature Control of Robotic Friction Stir Welding. University West, PhD Thesis, Production Technology, 2020, No. 33, 25 March 2020. https://doi.org/10.13140/RG.2.2.34010.70083.

- Pai-Chen Lin, , and Shihming Lo. “Development of Friction Stir Clinching Process for Alclad 2024-T3 Aluminum Sheets.” SAE International Journal of Materials and Manufacturing, vol. 9,

no. 3, 2016, pp. 756–763. DOI: https://doi.org/10.4271/2016-01-0505. Also

available free of charge at JSTOR, www.jstor.org/stable/26269126. Accessed 28 Feb.

2021.

- Mustufa Haider Abidi, Nabeel Ali, Hashmatullah Ibrahimi, Saquib Anjum, Dhruv Bajaj, Arshad Noor Siddiquee, Mohammed Alkahtani and Ateekh Ur Rehman: T-FSW of Dissimilar Aerospace Grade Aluminium Alloys: Influence of Second Pass on

Weld Defects. Metals 10, No. 4, 525. https://doi.org/10.3390/met10040525. 18 April 2020.

- Dhruv Shah, Vishvesh J. Badheka: Friction Stir Additive Manufacturing — A Review. In: Recent Advances in Mechanical

Infrastructure, Springer Singapore, 2021.

- Kush P. Mehta and Pedro Vilaça: A review on friction stir-based channeling. Critical Reviews in Solid State and Materials Sciences, (2021). DOI:

https://doi.org/10.1080/10408436.2021.1886042.

- William J. Arbegast: Friction Stir

Welding. After a Decade ef Development - It's not just welding anymore. Welding Journal, March 2006. Pages 28-35.

- João Miguel de Lima Fortunato: Friction Stir Weldbonding - Defect Inspection and Mechanical Characterization.

-

John A. Baumann: Production of

Energy Efficient Preform Structures (PEEPS). 15 February 2012.

- Q. Chu, W.Y. Li, H.L. Hou, X.W. Yang, A. Vairisa, C. Wang, W.B. Wang: On the double-side probeless friction stir spot welding of AA2198 Al-Li alloy. J. Mater. Sci. Technol., 2019, Vol. 35, Issue (5):

784-789. DOI: https://doi.org/10.1016/j.jmst.2018.10.027.

- Robotics Industries Association: Technology Watch: Aerospace Manufacturing on Board with Robots. 12 May 2016.

- Jeroen De Backer, Xingguo Wei, Jonathan Martin: Robotic FSW for three-dimensional components. SEEIIW2015,

Romania, 2015.

- Zhe Gao, Weihong (Grace) Guo (New Brunswick, NJ) and Xiaowei Yue (Blacksburg, VA): Optimal Integration of Supervised Tensor Decomposition and Ensemble Learning for In Situ Quality Evaluation in Friction Stir Blind

Riveting. in: IEEE Transactions on Automation Science and Engineering. Band 18, 1, Jan. 2021. https://doi.org/10.1109/TASE.2019.2955397.

-

Feng, XS., Li, SB., Tang, LN. et

al. Refill

Friction Stir Spot Welding of Similar and Dissimilar Alloys: A Review. Acta

Metall. Sin. (Engl. Lett.) 33, 30–42

(2020). https://doi.org/10.1007/s40195-019-00982-4.

-

What is Refill Friction Stir Spot Welding?

- Jian Wang, Yun Cheng, Bo Li and Cheng Chen: Effects of Multi-Pass Friction Stir Processing on Microstructures and Mechanical Properties of the 1060Al/Q235 Composite Plate. Metals 2020, 10(3), 298; https://doi.org/10.3390/met10030298.

- Yang Zhou, Shujin Chen, Jiayou Wang, Penghao Wang and Jingyu Xia: Influences of Pin Shape on a High Rotation Speed Friction Stir Welding Joint of a 6061-T6 Aluminum Alloy Sheet.

Metals 2018, 8(12), 987; https://doi.org/10.3390/met8120987.

- Dwight A. Burford, Maurizio Manzo, Hector Siller, Supreeth Gaddam, Anurag Gumaste, James Koonce, Aleandro Saez, Rajiv S Mishra: Submerged Bobbin Tool (SBT) Tunneling Technology. Symposium Friction Stir Welding

and Processing XII. 2023 TMS Annual Meeting & Exhibition. 19-23 March 2023, San Diego, CA.

- Marco Thomä, Andreas Gester, Guntram Wagner and Wolfram Fuerbeth: Application of the hybrid process ultrasound enhanced friction stir welding on dissimilar aluminum/dual‐phase steel and aluminum/magnesium joints. August 2019, Materialwissenschaft und Werkstofftechnik, 50(8):893-912.